Two boiler tube bending machines equip world-wide group

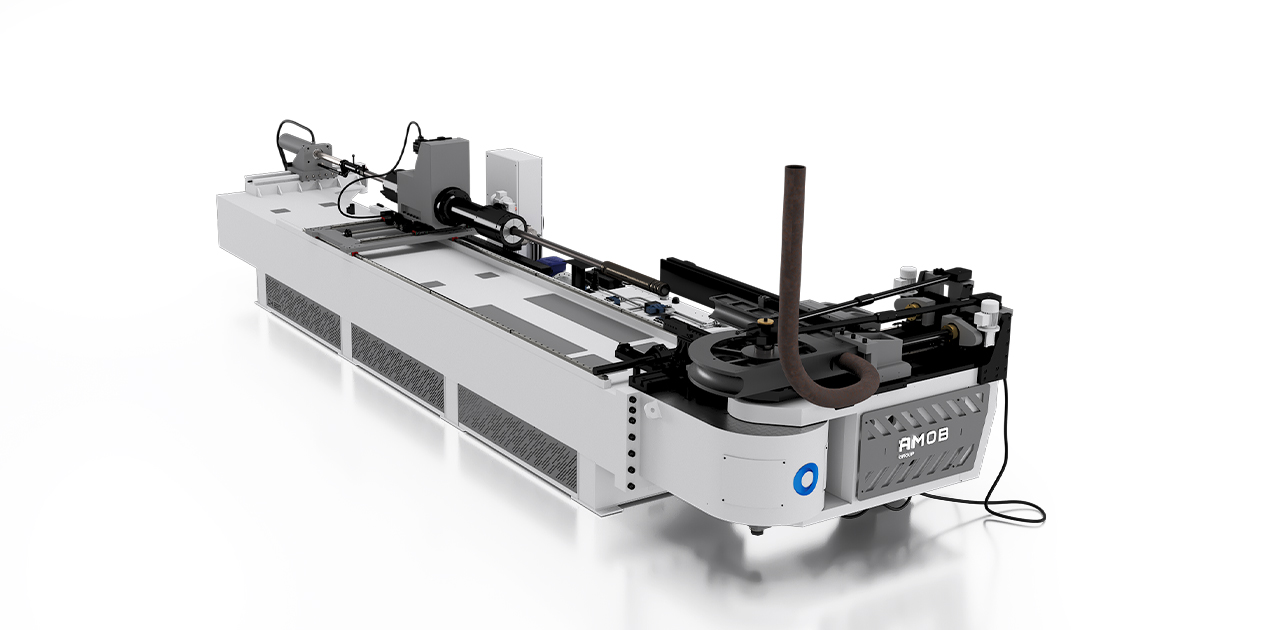

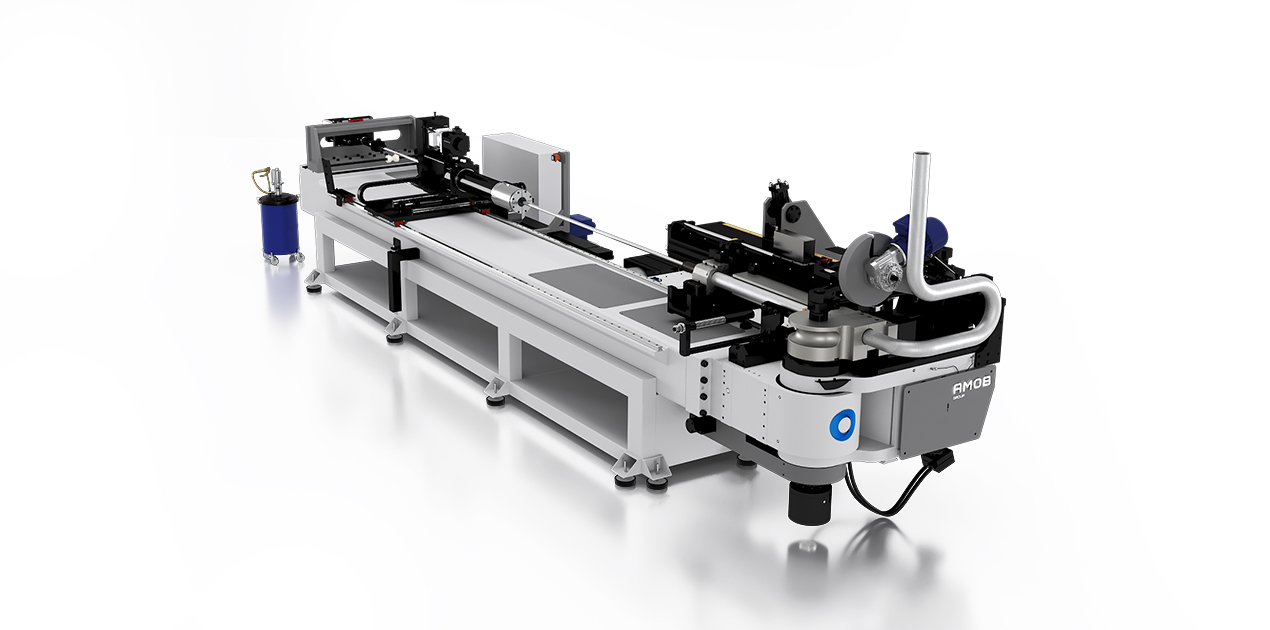

CH80CNC-B CH120CNC-B

Our costumer provides services of engineering planning and design, project management and consulting, construction, installation and commissioning, maintenance and repairs, as well as fabrication and prefabrication of parts and components in the industry and energy segment.

The two Boiler Tube Bending Machines – the CH80CNC-B and the CH120CNC-B give the customer more throughput and more capacity, therefore reducing lead times and increasing manufacturing abilities. The customer became conscious that their tube bending manufacturing cell was the biggest bottle neck in the process, and therefore needed modernising. The two older machines were creating lots of downtime, and the tooling was starting to have a detrimental effect on the quality of work.

The CH-B Series has the most efficient and innovative solution for producing extra-tight radius bends with minimal deformation and when we use the booster device, in conjunction with a fully hydraulic CNC bending machine, we enable precision parts replication with minimal process times as well as remove the possibility of human error.

This machine had already put us at the forefront of the market in terms of minimal elongation and deformation percentages and being the strongest supplier, AMOB were duly selected – quoting a turnkey package and the shortest lead time. This two were chosen to replace the old cell, not only improving the solution but also bettering it. With additional capacity and the new machine to increase throughput, the customer was able to eliminate the manufacturing bottle neck and improve quality of product.

Not only did they want to replace the old, outdated machine but they also wanted to bring the manufacturing cell into the 21st century. All AMOB CNC pipe benders offer this, as they are all technologically advanced and can be connected to different departments remotely. The client’s design and production departments can remotely access the machine to upload production drawings, access bend programs and have full control of the machine. The production department can access information such as production count, product cycle time, working time and downtime, as well as accessing and assessing any warning indicators.

The two Boiler Tube Bending Machines were successfully installed and commissioned along with a week’s training package in early 2018. Training was completed by both factory and local service engineers and the customer was able to launch full production across all two machines less than a week after delivery. The customer was extremely happy with the way AMOB handled the project life cycle and the additional turnkey package that was supplied.

If your company has a large tube bending cell overhaul requirement, then look no further than AMOB!